Vertical Pillow Bag Machines

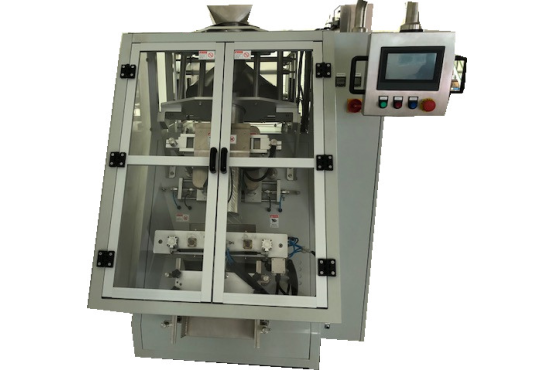

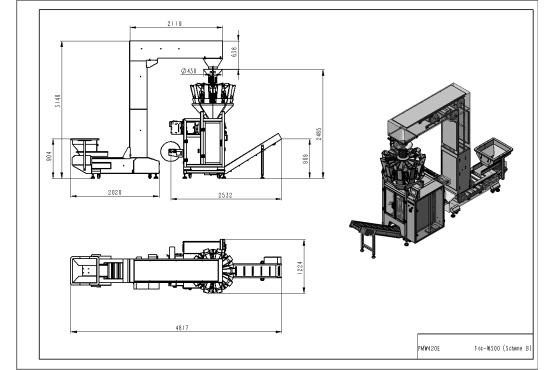

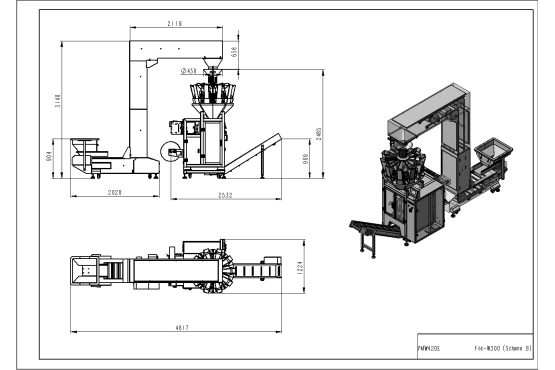

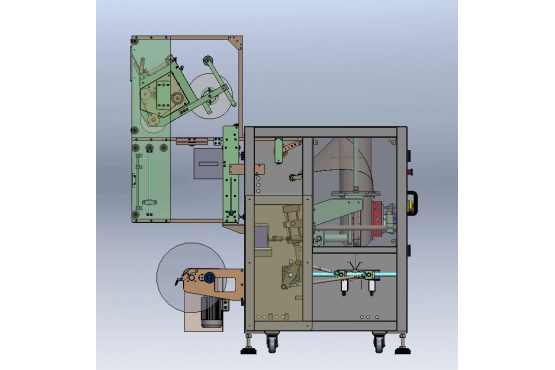

Using our vertical Nero-Pack pillow bag machines, you will achieve the optimal connection between production and packaging. Thus, the machine enables you to reach a further automation in your packaging process by forming, filling and capping the bags - all in one workflow. The vertical pillow bag machine is perfectly suitable for the automatic dosing of bulk and piece goods in the pastry and pasta sector or for snack packaging and small part packaging such as screws. The application of our vertical pillow bag machine (conveying, filling and capping) takes place in one workflow and is performed manually or automatically depending on the product requirement. The simple integration of conveyor and dosing systems (e.g. multiple-head scale) enables a flexible use. Individual adjustments to customized products are always possible thanks to the sophisticated technology of our machines. By using reeled flat films (transparent or printed), the packaging costs are kept low and an efficient work is guaranteed.

Technical Details

- optional stainless steel design for the food sector (IP 45, IP 65)

- applicable for bulk and piece goods, as well as for liquids and powders

- film processing also without print marks due to the bag length measuring device

- simple touch screen operation via color symbols

- permanently heated sealing systems

- simple and quick product exchange

- synchronization of printing, labeling or dosing systems

- integrated batch counter and print mark control

- individually storable product programs

Vertical Pillow Bag Machine: Product Video

Nero-Pack SBM-620 with Volumetric Filler and Label Dispenser

Nero-Pack SBM-620: Gift ribbon

Nero-Pack SBM-420: Pastries

Different Models:

* It is not possible to combine all maximum dimensions

** The output quantities per minute are averages depending on film type, thickness, product dimension and machine handling

Additional Options:

Improved handling:

- customized hoppers

- product adapted sorting tables

- operation via foot switch

Dosing units:

- linear scale

- multiple-head scale

- vibratory conveyor head

- auger filler

- volume dosing

Print and stamping units:

- individual labeling systems

- print unit and label dispenser

- hot stamping system / printer

- thermal transfer printer

Printed films: print mark control

Punching tools: euro standard holes or round perforation

Usable bags: stand-up pouches, side-gusseted bags