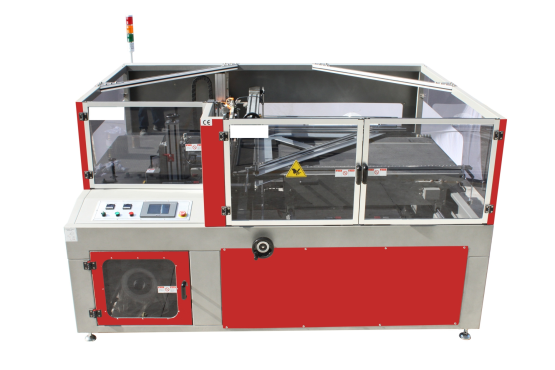

Automatic Side Sealing Machine (up to 60 cycles/min)

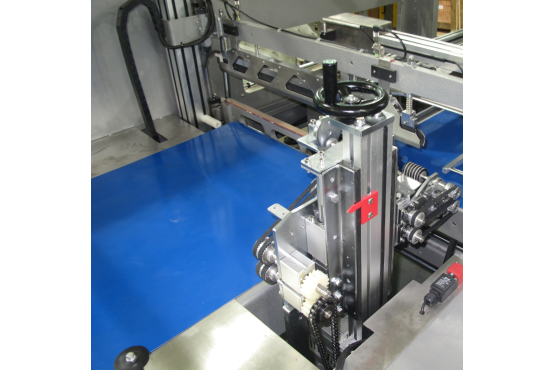

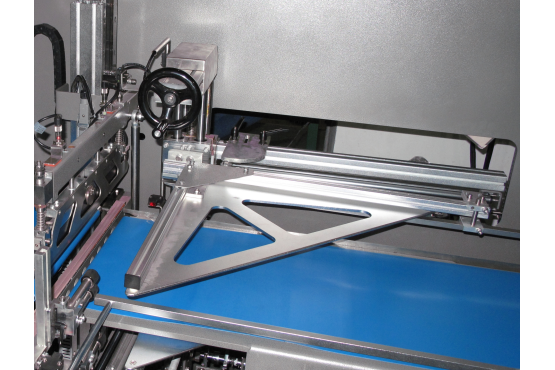

The side sealing machine guarantees extremely stable side seams for all films. The film is processed by three sided sealing of a center folded film (fine shrink film or PE fine shrink film). The use of our film sealing machines enables the user to pack over-sized products. The fast conversion to other product sizes guarantees an efficient and cost-effective workflow. The vertical pillow bag machine impresses by its performance and innovative design at highest standards. Another great advantage of our DEAPSS line is the automatic product centering system. With this function, the machine adjusts automatically to different container sizes and feeds them centrally. The second special feature, the permanently heated side sealing unit, enables the user to pack even over-sized products.

Technical Details

- cross-sealing and permanent side sealing

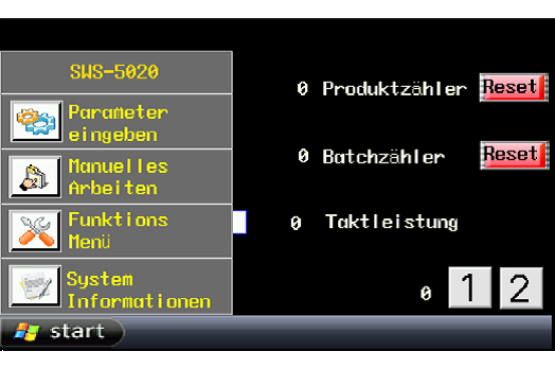

- simple operation due to digital program selection with individually storable programs

- servo-controlled sealing stamp

- discrete temperature control for the sealing knifes (lengthwise/crosswise)

- bundlings of one or more products possible

- automatic winding of film waste

- permanently heated and Teflon-coated sealing knifes (kit)

Different Models:

*It is not possible to combine all maximum dimensions

**The output quantities per minute are averages depending on film type, thickness, product dimension and machine handling.

Additional Options

- Film folding device: Longer production periods due to the use of flat films, increase of production capacities due to a higher amount of running meters, faster retooling times, simple application for printed films

- Label / print unit: Barcode or label printing, upstream or downstream

- Stainless steel construction: Machine components made of stainless steel for direct contact with food

- Conveyor belt kiss function: Particularly for small or short product groups

- Feed system: Product-specific feed sytems (pusher, side conveyor belt)