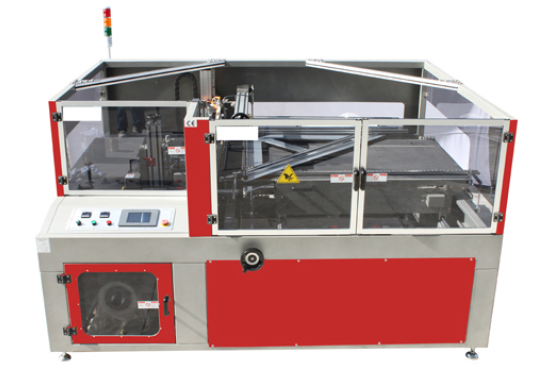

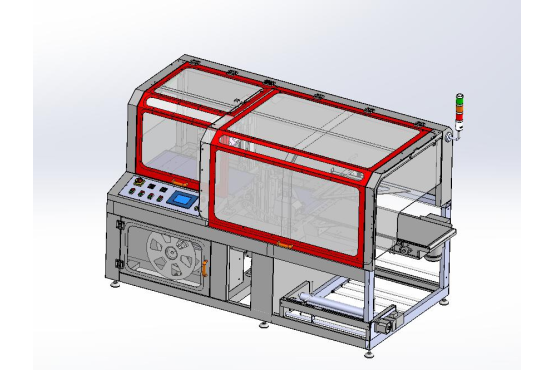

Box Motion (Side Sealing Machine, up to 100 cycles/min)

The Box Motion Side Sealing Machine facilitates a continuous packaging process without product downtime (stop&go). The trailing transverse sealing "flies" towards the product and increases the packaging performance significantly compared to a clocking side sealing machine. The film processing happens by three-sided sealing of a center folded film. The integrated side sealing gives you the opportunity to pack both very small and over-sized products in large quantities. The fast conversion to other product sizes guarantees an efficient and cost-effective workflow.

Technical Details

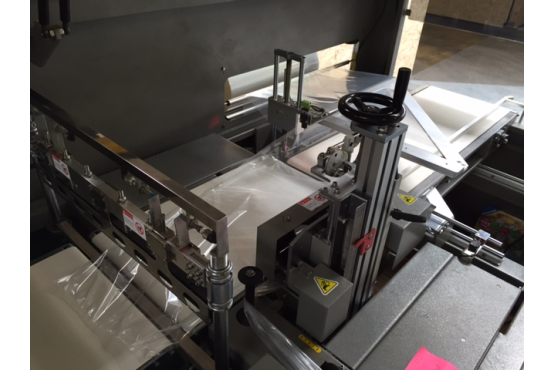

- permanently heated transverse and side sealing

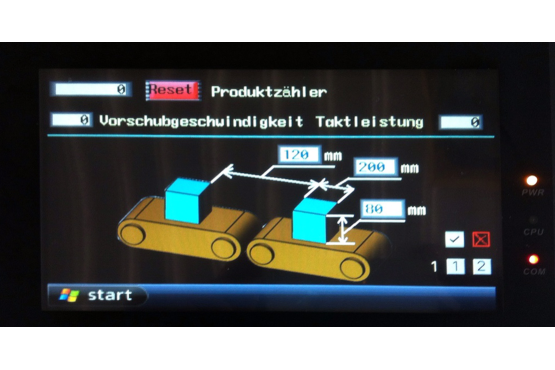

- simple touchscreen operation through color symbols

- individually storable programs

- bundlings of one ore more products possible

- stainless steel version available

- automatic winding of film waste

- integrated batch counter and print mark control

- safety protection cover / emergency signal lamp

- continuous longitudinal sealing, no limit on product lengths

- servo controlled motor drive for sealing machines and conveyor belts

- perforation needle rolls, stored on a rubber roller

Data Sheet Box Motion Side Sealing Machine DEAPSS-5020BM

| Model | DEAPSS-5020BM |

|---|---|

| Usable films (center folded) | POF / PP / PE |

| Sealing mechanism 1: | longitudinal sealing (pneumatic) |

| Sealing mechanism 2: | trailing transverse sealing (pneumatic) |

| Sealing knife width (crosswise): | 500 mm |

| Maximum product height: | 199 mm |

| Maximum format width (W + H): | 450 mm* |

| Maximum reel size (L x Ø): | 650 x Ø 300 mm |

| Machine size (L x W x H): | 2250 x 1700 x 1500 mm |

| Conveyor belt speed: | 35 m / minute |

| Connected load (maximum): | 4,5 kW |

| Supply voltage: | 400 V / 3-phases |

| Sealing process: | up to 100 pieces / minute** |

| Air pressure (dry air): | 6,0 bar |

| Machine weight: | approx. 450kg |

* It is not possible to combine all maximum dimensions

** The output quantities per minute are averages depending on film type, thickness, product dimension and machine handling.

Additional Options

- Film folding device: Longer production periods by the use of flat films, increased production capacity due to more film running meters, faster changeover times, easy application for printed films

- Labeler / Printing unit: Barcode or label printing, upstream or downstream

- Stainless steel construction: Stainless steel machine components for direct contact with food

- Conveyor belt kissing function: Especially for small/short product lines

- Feeding system: Product specific feeding systems (Pusher, lateral conveyor belt, etc)