L-Bar-Sealer

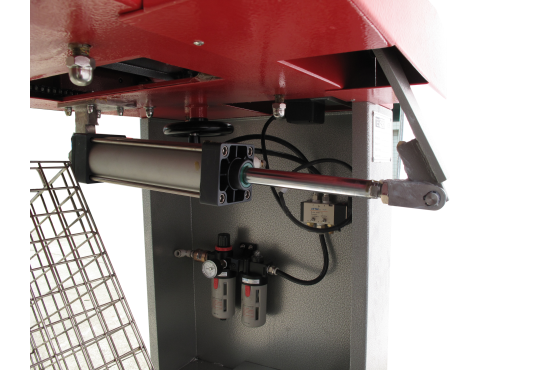

With tbs-pack's semi-automatic film sealing machine (L-bar-sealer) from the WSG line, your products can be packed quickly and cost-effectively in one working cycle by using film separation sealing. The product is inserted into the semi-automatic packaging machine and the release happens in a manual or pneumatic way. The sealing frame opens automatically and the product can be fed optionally into a separate shrink tunnel. The high-quality components and our mature impulse wire technology guarantee high-strength sealing seams and low-maintenance operation.

Due to its easy handling, the packaging machine ensures flexible and time-saving packaging at high throughput rates.

Customer specific sealing frame sizes or permanently heated sealing knifes are available on request.

Technical Details

- solid design due to steel frame construction

- individually combinable with different shrink tunnels

- Teflon-coated impulse heating tape (reduction of film adhesion)

- electronic setting of sealing time, outfeed conveyor speed and sealing cycle (in pneumatic operation)

- electromechanical closure of the sealing frame via holding magnet

- wheeled L-bar-sealer with parking brake - easy handling

- movable film slide including film perforation unit

- optional pneumatic L-sealing funktion possible (foot switch, timer, "opening/closing", two-hand control)

- as an option: permanently heated L-bar-sealer

Practical Usage Possibilities at a glance:

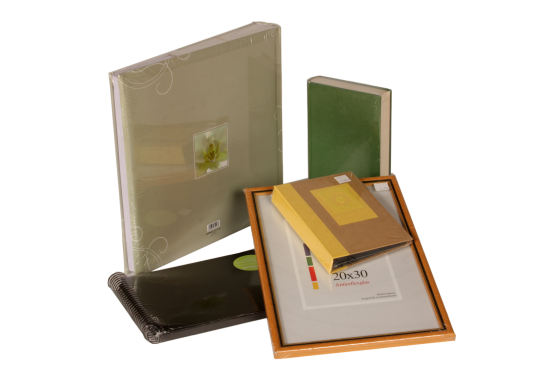

- Book packaging, catalogues

- Cardboard packaging, mailings

- Food packaging

- CD's, DVD's, brochures

- Small parts, bundlings etc.

L-Bar-Sealer: Product Video

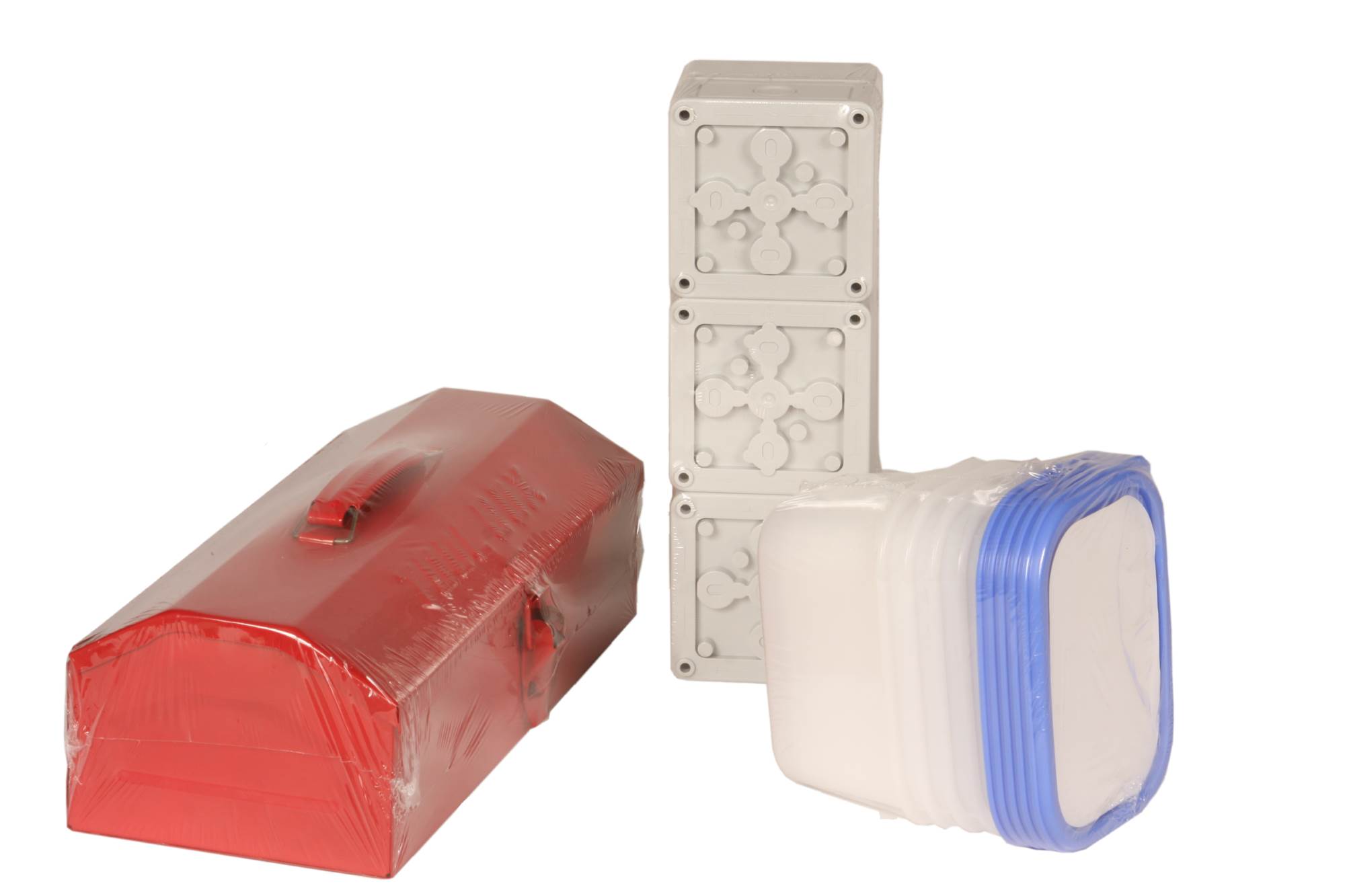

Application Example: WSG-5070 with STA-6540: Shrinking of Tools

Application Example: WSG-6080 with permanently heated sealing knife

Different Models:

* It is not possible to combine all maximum dimensions

** The output quantities per minute are averages depending on film type, thickness, product dimension and machine handling.